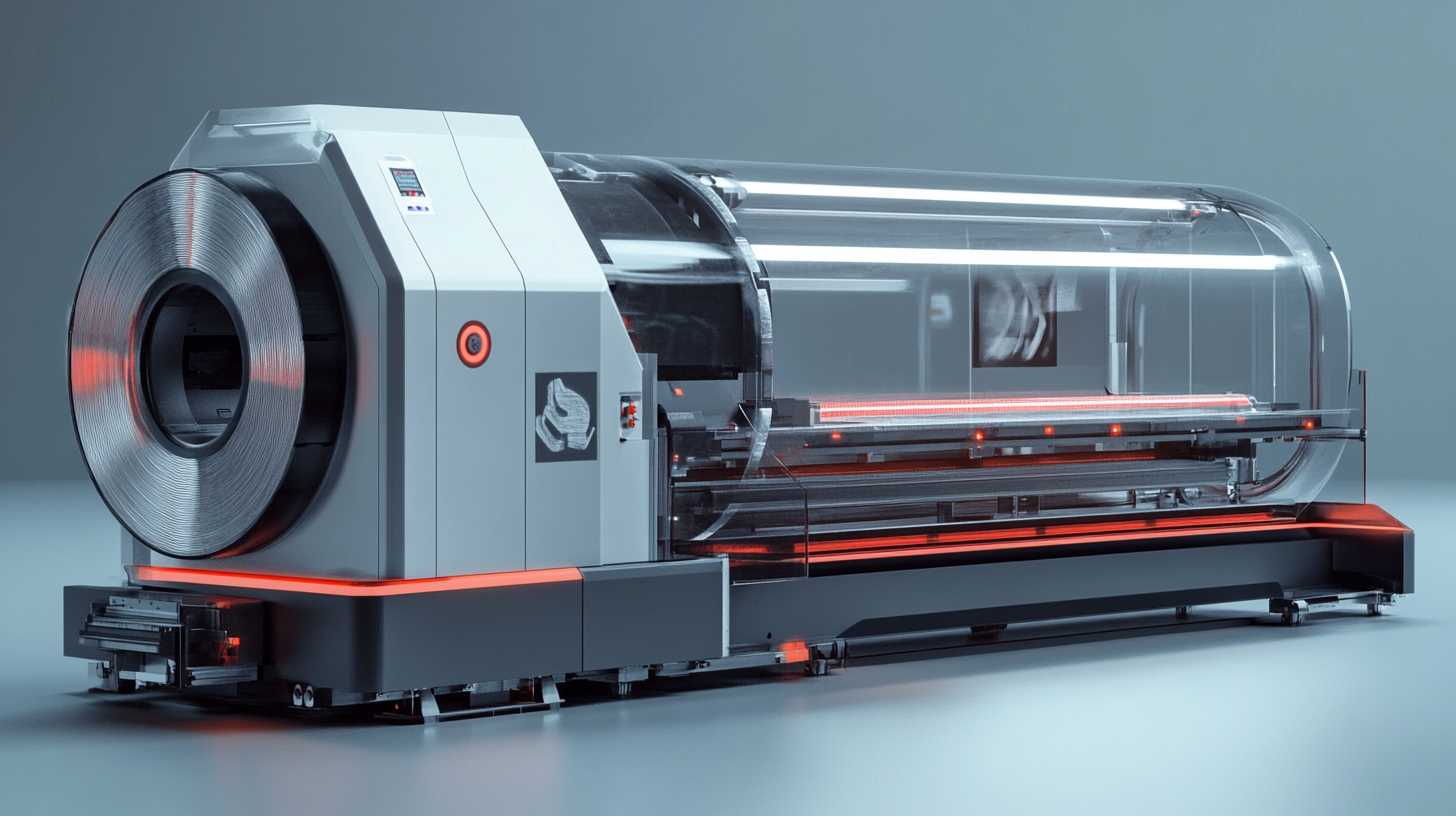

Future of Wrapping Machines in Manufacturing 2025 Essential Features and Considerations

By 2025, technological advancements and changing consumer demands would continue transforming the manufacturing landscape. One of the important factors associated, among others, is wrapping machines, which is a great boosting tool to productivity and efficiency in packaging processes; within the assumption, these machines also ensure that the products are packaged into good quality while optimizing supply chain operations. Obviously, packaging forms an important part of ensuring product safety in ways that it can be understood from the outside. Future features and practical aspects of wrapping machines are primarily important to manufacturers for maintaining a competitive position in the rapidly changing market.

In the coming years, innovations such as automation, smart technology, and sustainability will alter the operation of wrapping machines. Manufacturers should not only think about the machine, but also how efficient, cost-effective, and environmentally friendly their operations are. Delving into the primary features and considerations for wrapping machines in 2025 shows that one will keep moving even before these developments come into place, preparing manufacturing companies to compete better within an increasingly convoluted industry.

Emerging Technologies Shaping the Future of Wrapping Machines

The future of wrapping machines in manufacturing will soon undergo major changes owing to emerging technologies that focus on efficiency and adaptability. One of the most exciting roads that wrapping machines are going down is AI and Machine Learning. With the help of these technologies, wrapping machines will be able to interrogate real-time production data, optimizing wrapping processes for different product sizes and shapes, and materials. By applying predictive algorithms to avoid downtime and minimize material wastage, manufacturers contribute to a more sustainable and profitable operation. Simultaneously, the advent of IoT is also redefining the interaction of the wrapping machine within the manufacturing ecosystem. These IoT devices offer interconnectivity within the machine and central management systems, bringing workflow automation to the next level. This interconnectivity not only enhances operational efficiency but also gives better visibility about the machine's performance and maintenance requirements. As data analytics find more acceptance within these realms, organizations will be able to leverage such insights to make better operational decisions, thus diminishing bottlenecks and improving overall productivity. Robot automation is yet another major driver in wrapping machine evolution. Advanced robotics can perform complex wrapping tasks that require precision and speed, often beyond human capabilities. Increasingly versatile, these days, robots are capable of handling a variety of packaging formats and materials with minimal reconfiguration. Labor shortages already faced in many parts of the world will see an increase in the adoption of robotic wrapping solutions, resulting in fast, intelligent production lines capable of responding to the fickle demands of markets. This technological synergy is set to become the new narrative of wrapping machines in terms of intelligence, efficiency, and adaptability vis-a-vis forthcoming challenges in manufacturing.

Key Features for Maximizing Efficiency in 2025 Manufacturing

The advances that are coming with wrapping machines are bound to redefine efficiency and productivity in the manufacturing arena by 2025. The recent Smithers Pira report estimates that by 2025, the global wrapping machine market will reach $12.5 billion, propelled by innovations enhancing workplace efficiency. Manufacturers should aim for specific key features in their wrapping machines to maximize efficiency.

Automation, in particular, is one major feature. According to predictions made by the World Economic Forum, automation may displace around 85 million jobs by 2025; so, in the same connection, it shall also create opportunities for 97 million new jobs. The introduction of automated wrapping machines is an excellent way of drastically reducing labor costs and minimizing human error, thereby allowing companies to maintain their levels of output while redirecting human resources toward more strategic functions. By utilizing smart technology that interfaces with production lines, even smoother processes can be facilitated within the agile manufacturing environment.

Energy efficiency has also become a matter of increasing relevance. A report conducted by the International Energy Agency states that the manufacture's bettering energy efficiency will help cut down energy consumption by 25% by the year 2025. Wrapping machines that use energy-efficient motors and heat recovery systems would minimize operating costs and comply with increasingly stringent environmental regulations. These features together ensure the company not only keep ahead of regulatory requirements but also cater to eco-minded consumers.

Lastly, attention to flexibility remains an important consideration in wrapping machine design. Owing to custom packaging demands, machines adapting to different package sizes and materials with ease will become crucial. Findings state that 60% of manufacturers are looking for solutions to enhance rapid changeovers and support diversifications in product offerings. By investing in flexible wrapping technology, companies would be able to compete in an increasingly customizable market.

Sustainability in Wrapping Machines: Trends and Innovations

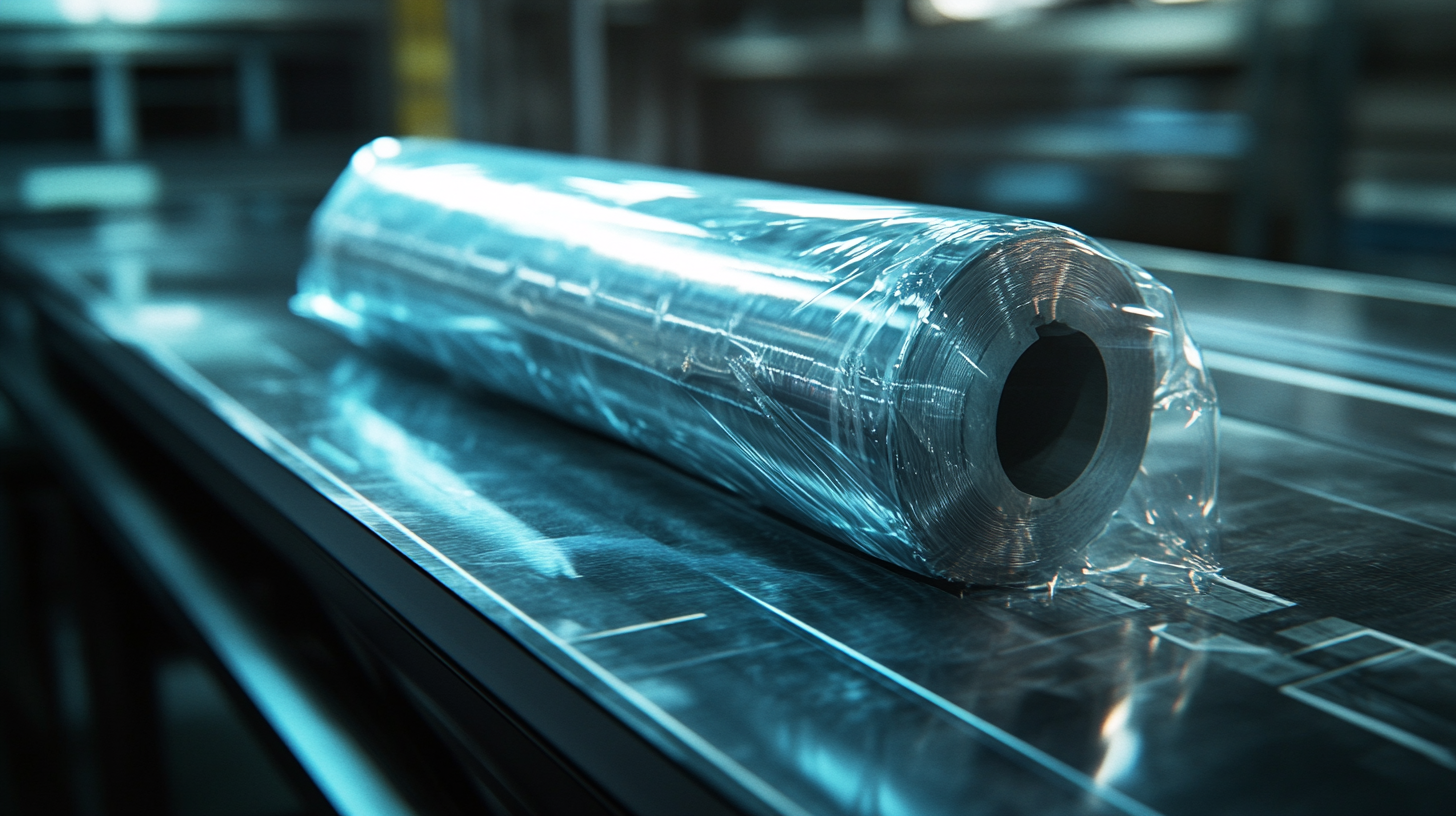

Sustainability in wrapping machines has become a key concern for the manufacturing industry, especially as more companies are called to meet rising expectations for eco-friendly practices. A recent Smithers Pira report suggests that the global market for sustainable packaging is expected to hit $1 trillion by 2025, signaling that the shift to more environmentally-conscious manufacturing processes is gaining momentum. This in itself encourages manufacturers to start innovating towards making biodegradable wrapping machines incorporating sustainable materials and technologies.

Biodegradable and recyclable material use is another one of the main trends with respect to wrapping machines. As per the Flexible Packaging Association's 2022 study, nearly 30% of consumers show a preference for products that use sustainable packaging, thus leading manufacturers to adopt materials that lessen their environmental footprint. Packaging with compostable films and recycled content not only caters to consumer expectations but also aligns with global sustainability goals by substantially reducing landfill waste and promoting a circular economy.

Technological advancement is yet another critical factor concerning environmental sustainability and will continue to play a very important role in sustainable packaging technologies. According to the International Energy Agency, energy savings of up to 25% can be achieved using energy-efficient drives and intelligent automation systems in packaging. Another energy-efficient method can be the use of smart wrapping machines with sensors that optimize the usage of materials so that the packing process is as efficient as possible and waste is kept to a minimum. This trend is a manifestation of the commitment to sustain environmentally responsible practices into the future growth of the manufacturing sector.

Integration of IoT and Automation in Modern Wrapping Solutions

The packaging industry will see revolutionary changes by 2025 through the integration of IoT and automation into modern wrapping solutions. With the global industrial machinery market estimated to reach nearly $7.145 trillion in 2024, the demand for wrapping machines that effectively utilize this technology is growing at a rapid rate. This increasing demand is further supported by globalization and the expansion of the food processing industry, estimated to grow at a CAGR of 9% from 2025 to 2034.

The implementation of edge AI is yet another factor that can turn the tables in wrapping solutions. The edge AI market is expected to grow at a stellar CAGR of 24.8% over the years 2025-2034 and has numerous applications in manufacturing and logistics environments. Hence, as companies continuously seek ways to become more efficient and minimize operational costs, automated processes for wrapping integration with AI have now become an imperative. In modern times, wrapped figuring out production through the automated process becomes really useful. Not only this but also assures better quality control and higher tracking ability with smart packaging solutions.

Another surge in growth in demand for contemporary industrial packaging solutions is being spurred by e-commerce and logistics. The industrial packaging market is expected to cross $68.7 billion in 2024, with steady growth at 4.6% estimated through 2034. As the demand for innovative wrapping machines that are able to cater to multiple products and provide flexible packaging solutions gathers momentum, manufacturing leaders will have to put special focus on IoT and automation if they intend to remain relevant in such a fast-paced environment.

Challenges Facing the Evolution of Wrapping Machines in Manufacturing

It is pertinent fact that by 2025 the packaging machinery scene will change significantly, with various challenges expected to shape the application that will transform wrapping machines. A PMMI report indicates that most of the applications of AI are currently putting their footprints into the packaging machinery. Such a change is more in terms of evolution rather than revolution. Therefore such adaptation in AI technologies will always be faced by manufacturers with intrinsic challenges such as the labor crunch and increasing operational costs to sustain/output productivity and competitive advantage.

Interestingly, the global packaging machinery market is expected to grow by 0.5%, wherein intelligent automation will play a very important part in improving efficiency and waste reduction. The increasingly demanding regulatory requirements, together with the demand from consumers for sustainability, will, therefore, demand advanced wrapping machines that can perform integrated functionalities. Besides, advances in automation technology will not only improve line productivity but will also be a way in which the goal of sustainability will be realized through reductions in energy and materials.

Advanced packaging technologies are also evolving in parallel with the semiconductor market, creating additional avenues for new growth. The growth trajectory above is most likely going to apply to the packaging machinery space as the industry shifts to increasingly complex methods of 3D hybrid bonding, which are those advanced packaging technologies. Smart examples will, in this light, also immensely benefit from the improvement of other processes, such as labeling and packing that reflect a wider trend of intelligent automation currently manifesting across industries.